PIPECONTROL DESCRIPTION

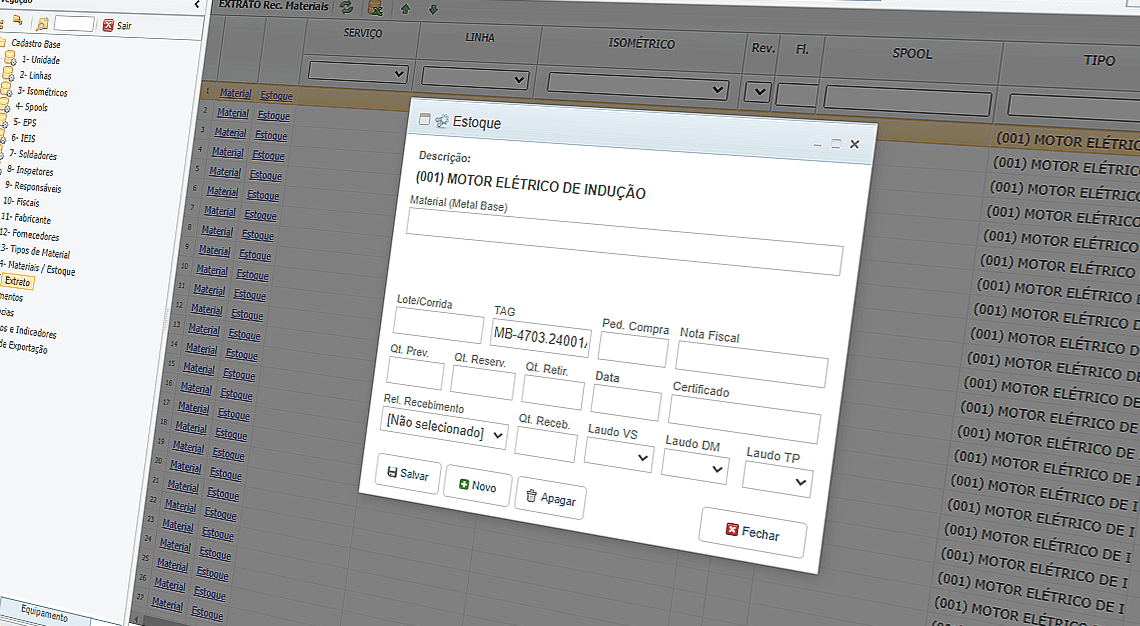

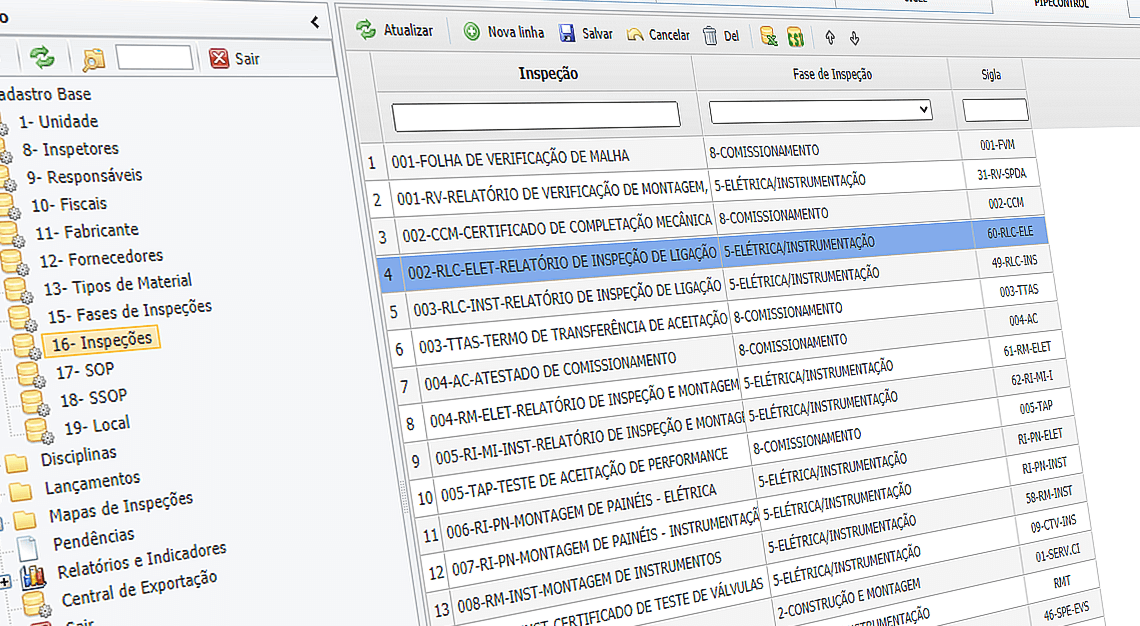

PIPECONTROL is used for fabrication and assembly of pipes and accessories control, with resources that integrate Commissioning and Quality Inspections. processes. It provides high traceability of materials, inspections and preservation and monitoring reports. PIPECONTROL makes the tests flow (workflow) designed by an Aligned Commissioning of an enterprise possible. It also archives inspections made by Quality staff.

Main features:

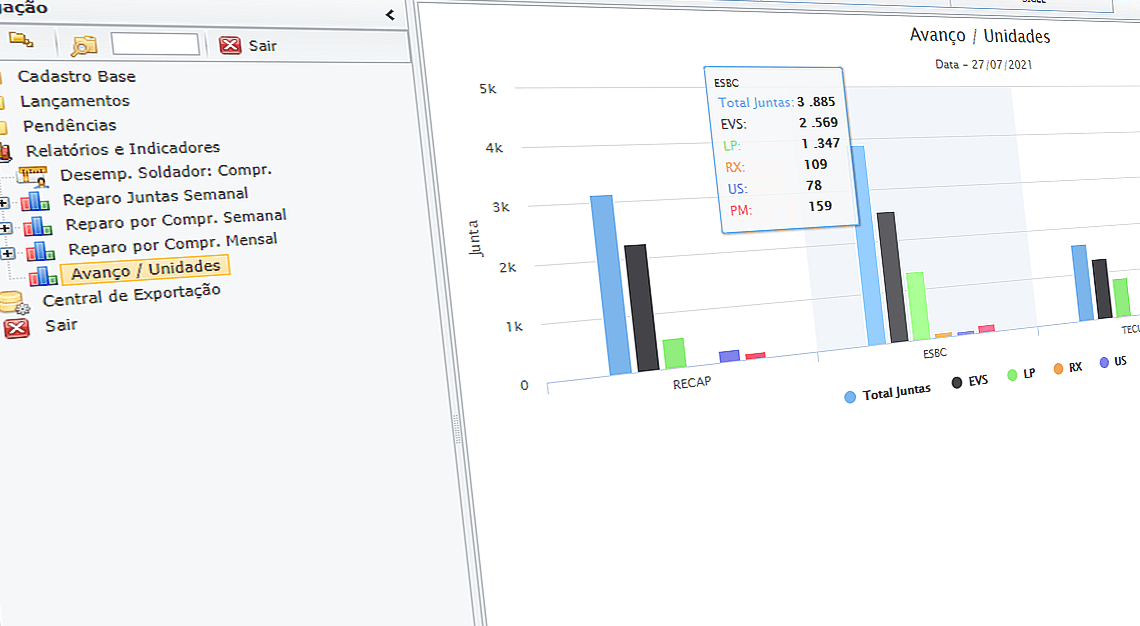

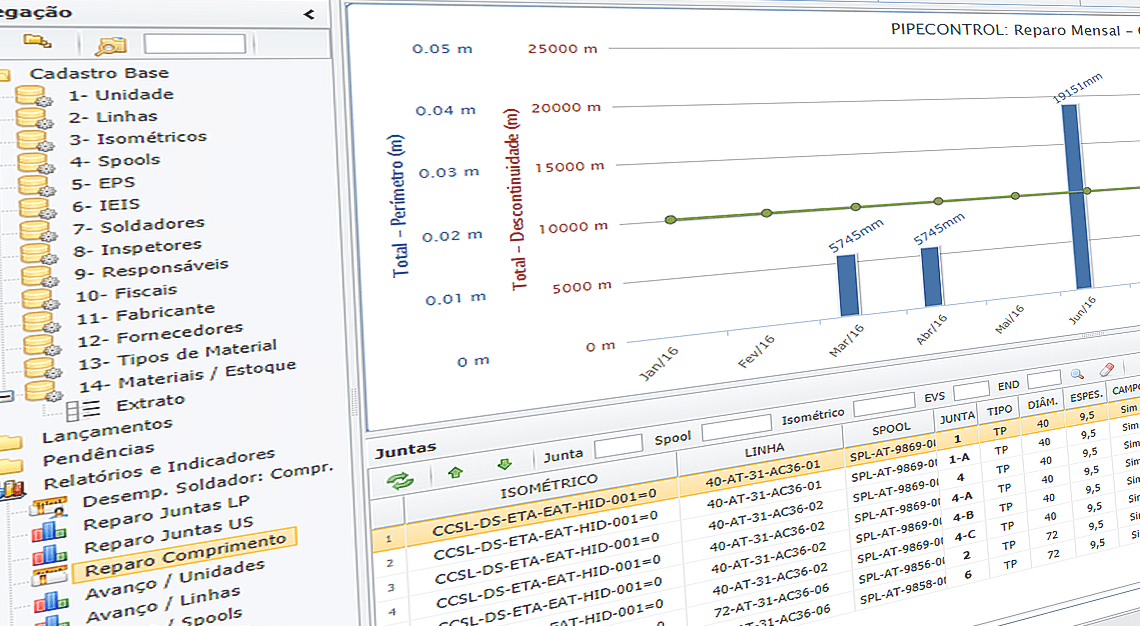

1. Weekly Repair Index: Track Product & Process quality simply and quickly.

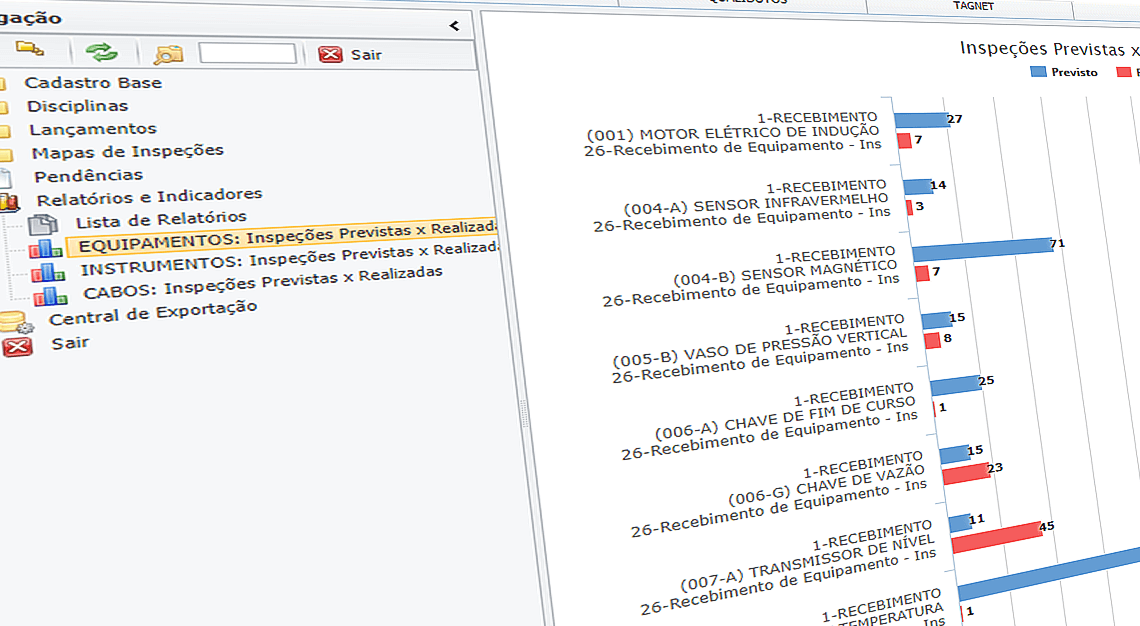

2. inspection progress index: Manage and track all inspections performed by PIPECONTROL.

3. Interactive Joint Map: Keep track of all inspections carried out and also have access to the scanned documents scanned documents at the click of a mouse.

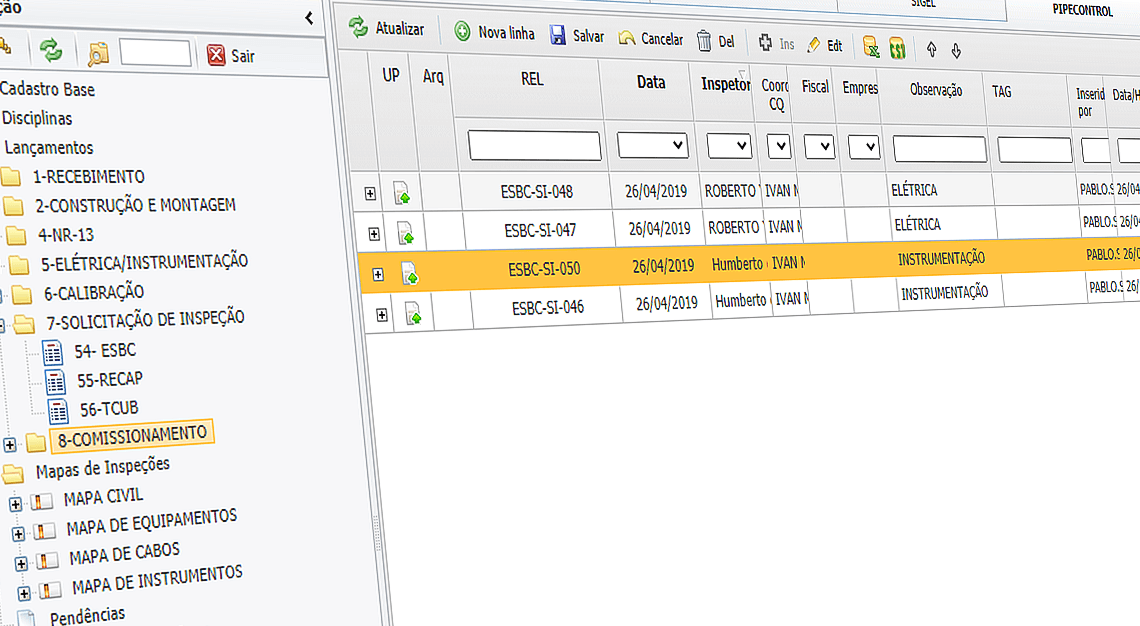

4. Reports generated in the software: Record all inspections within PIPECONTROL, generate the controlled form automatically and get the indicators directly from the platform.

5. Digitized reports: Scan and save reports on the platform itself.